By:Sherry Date:April-23-18

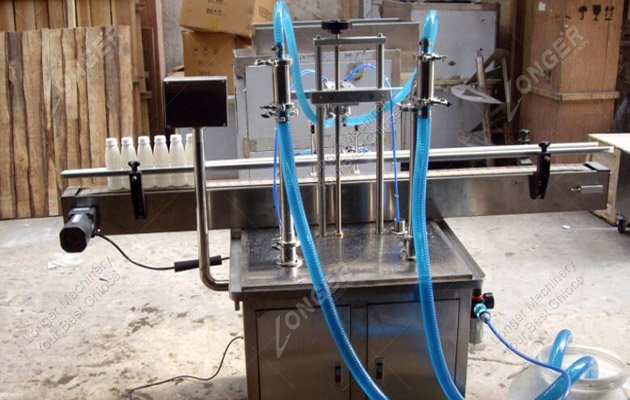

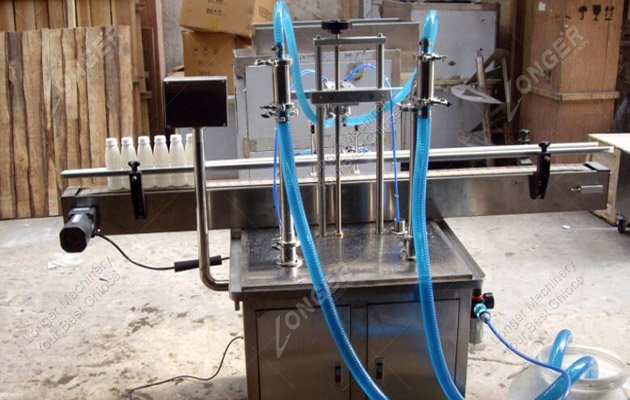

Now there are many

bottle filling machine in the market. These machines always have following advantages:

1. Adopt touch screen operation interface, simple operation, PLC control system, fast operation, stable performance and excellent quality.

2. Volume measurement and quality measurement can be converted freely.

3. Unique filling head design ensures no leakage during the filling process.

4. The electric and gas components are all made of fine components to ensure the stable operation of the whole machine.

5. Use power filling, no need to install high tank, simplifying the installation process and improve the filling efficiency.

Machines produced by different manufacturers have different advantages. But how to choose a suitable machine?

1. The productivity of the

filling machine reflects the production capacity of the production line directly. So the higher the productivity, the better the economic benefits it produces. In order to improve the quality of the product, a high-precision, high-level filling machine should be selected. However, the price of equipment has also been increased correspondingly, which has increased the unit cost of the product. Therefore, when selecting the filling machine, it should be combined with the requirements of the production process to comprehensively consider the relevant factors.

2. The technological scope of the filling machine refers to its ability to adapt to different production requirements. The wider the range of the process, the better the utilization of the equipment. And one machine has a wide range of materials and specifications. So if you want to fill different raw materials, you should choose a filling machine with a wide filling range.

If you have any demand about filling machine, please contact us for free.

Email:sherry@machinehall.com

skype:live:machinehall.sale

phone/whatsapp:+8618539931566